Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Optimization of Rigid Pavement

Authors: Abhishek Pandit, Abhishek ., Dr. Hemant Sood, Er. Jyothi P. M.

DOI Link: https://doi.org/10.22214/ijraset.2022.41699

Certificate: View Certificate

Abstract

The construction of national highways nowadays is preferred by using rigid pavements as they are durable, have the high flexural strength, can withstand different heavy axle loads, higher design span and moreover they can sustain adverse environmental conditions more efficiently with better ease. Considering their remarkable qualities, the national highways should be constructed by providing the tied shoulders and dowel bars in the transverse joints because they can better resist the fatigue accumulations on the slab with minimum safe thickness which ultimately leads to reduction in the cost of making the road efficiently. In this chapter, for the two different CBR conditions (CBR-9 & CBR-10) and three concrete mix design grades namely (M40, M45, M50) along with different shoulders and dowel bars conditions, the trial methods were carried on the IRC-58 Software for bottom-up cracking fatigue analysis for single and tandem axle for day-time (6 hour) traffic and positive temperature differential and top-down cracking fatigue analysis for single, tandem and tridem axle for day-time (6 hour) traffic and negative temperature differential for evaluating the flexural stresses and cumulative fatigue damage values for the slab having dimensions of (3.5m x 4.5m). For determining the safe design, different trails on the thickness parameter of the slab were being adopted so as to get the cumulative fatigue values of BUC and TDC for single, tandem and tridem axles less than one. The results obtained showed that for which grade and CBR condition, the values of flexural stresses and cumulative fatigue damage determined is maximum. It was concluded that the rigid pavements should be constructed by using higher grades like M45 and M50 as the fatigue stresses and cumulative fatigue damage values due to variable single, tandem and tridem axle load repetitions obtained are less as compared to M40 grade.

Introduction

I. INTRODUCTION

The construction of national highways nowadays is preferred by using rigid pavements as they are durable, have the high flexural strength, can withstand different heavy axle loads, higher design span and moreover they can sustain adverse environmental conditions more efficiently with better ease. The pavement construction should be able to provide a rideable surface with suitable skid resistance, good light reflecting properties, and low noise pollution. A highway pavement is a structure made up of stacked layers of processed materials over the natural soil sub-grade, with the primary purpose of distributing vehicle loads to the sub-grade. The ultimate goal is to ensure that the transmitted stresses caused by wheel load are decreased to the point where they do not exceed the sub-bearing grade's capability. There are two types of pavements that are commonly used for this purpose: flexible pavements and rigid pavements.

A. Rigid Pavement

Rigid pavements have enough flexural strength to disperse wheel load strains across a larger region. Rigid pavements are laid directly on the prepared sub-grade or on a single layer of granular or stabilised material, as opposed to flexible pavement. This layer can be referred to as the base or sub-base course because there is only one layer of material between the concrete and the sub-grade. The slab action distributes force in rigid pavement, and the pavement behaves like an elastic plate sitting on a viscous medium. Depending on the soil strength and loading circumstances, reinforcement is built into the slab. Surface courses made of pre-stressed concrete slabs can also be employed. For rigid pavement, Portland cement concrete is commonly utilised as the principal structural element. Depending on the soil strength and loading circumstances, reinforcement such as dowel bars and tie bars are used in the slab so as to transfer the loads to the other slab and to hold the slab in the firm and rigid condition.

B. Design Governing Factors

The main factors governing design of rigid pavements are design period, design lane, design commercial traffic volume, composition of commercial traffic in terms of single, tandem, tridem and multi-axles, axle load spectrum, tyre pressure, lateral placement characteristics, directional distribution, strength of foundation including CBR and modulus of subgrade reaction(k) data, temperature consideration, flexural strength of concrete, expected repetitions, allowable repetitions (n) and stress computations, type and number of dowel and tie bars used and climatic considerations. Considering their remarkable qualities, the national highways should be constructed by providing the tied shoulders and dowel bars in the transverse joints because they can better resist the fatigue accumulations on the slab with minimum safe thickness which ultimately leads to reduction in the cost of making the road efficiently.

II. EXPERIMENTAL WORK

A. Design Procedure

- For bottom-up cracking, the flexural stress at the edge due to the combined action of single or tandem rear axle load and positive temperature differential is considered. This stress is calculated by using the regression equations. Similarly, for assessing the top-down fatigue damage caused by repeated cycles of axle loads and negative temperature differential, flexural stress can be estimated using regression equations.

- Firstly, for the given design data of loads and their axle proportions, design traffic volume is calculated which depicts cumulative no. of commercial axles repetitions during the design period of 30 years for the BUC analysis for 6 hr. period during day and TDC analysis for 6 hr. period during night which was further being calculated according to the proportion of the axles considered. Corresponding to the different mid loads of single, tandem and tridem axles considered, Expected Repetitions is calculated according to their proportions taken. The stress ratios were optimized corresponding to flexural stresses determined from the regression equations which further evaluate the values of allowable repetitions of axles.

- For the estimation of fatigue damage, ratio of expected and allowable repetition is calculated. If the sum of cumulative fatigue damages due to wheel load and curling stresses at the bottom and the top is less than 1, the pavement is safe. Thus if CFD (BUC) + CFD (TDC) ≤ 1, the pavement is SAFE from large scale cracking as the concrete slab undergoes fatigue damage through crack growth induced by repeated cycles of loading.

B. Design Data

- Axle Load Data: To estimate the repetitions of single, tandem, and tridem axles in each direction predicted during the design period, data on axle load spectrum of commercial vehicles is used for optimizing the flexure stresses and fatigue damage by working out the bottom up cracking and top down cracking analysis.

2. The design period of 30 years is considered and design of lane 4-lane divided is considered.

3. Temperature Consideration

- Max. day-time Temperature Differential in slab (for bottom-up cracking) = 16.8ºC (Bihar)

- Night-time Temperature Differential in slab (for top-down cracking) = 13.4ºC

4. For CBR-9& M50

- 28-day Flexural Strength of cement concrete grade for M50 = 5 MPa

- Modulus of subgrade reaction corresponding to CBR-9= 52.67 MPa/m

- Effective modulus of subgrade reaction of foundation, MPa/m= 292.34 MPa/m

III. RESULTS

The calculations are carried out in IRC-58 Software, for evaluating the safe design, different trails on the thickness parameter of the slab were being adopted so as to get the cumulative fatigue values of BUC and TDC for single, tandem and tridem axles less than one.

A. For CBR-9, M50 Grade (No Tied Concrete Shoulders+ Transverse Joints Have Dowel Bars)

- Radius of Relative stiffness=0.70584 m

- Trial Thickness of Concrete Slab = 0.305m

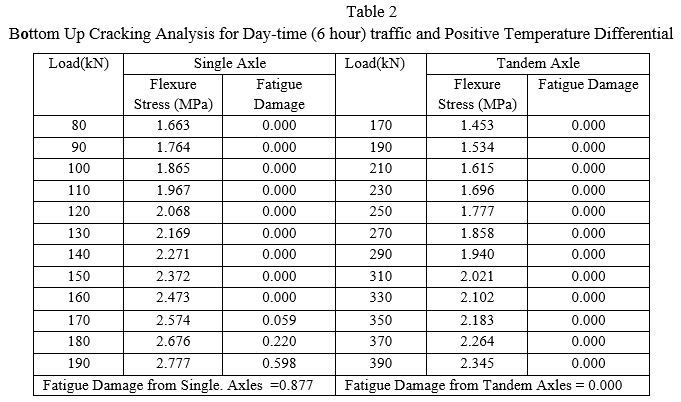

3. Total Bottom-up Fatigue Damage due to single & tandem axle loads = 0.877+0.000=0.877

Total Top-Down Fatigue Damage due to single, tandem & tridem axle load = 0.000+0.000+0.000=0.000

Sum of CFD for BUC & TDC= 0.877< 1, therefore design is SAFE.

???????B. For CBR-9, M50 Grade (Tied Concrete Shoulders+ No Transverse Joints Have Dowel Bars)

- Radius of Relative stiffness=0.67965 m

- Trial Thickness of Concrete Slab = 0.29 m

4. Total Bottom-up Fatigue Damage due to single and tandem axle loads = 0.000+0.000=0.000

5. Total Top-Down Fatigue Damage due to single, tandem & tridem axle load = 0.325+0.556+0.041=0.922

Sum of CFD for BUC & TDC= 0.922 < 1, therefore design is SAFE.

Conclusion

1) The rigid pavement having slab thickness of 0.305m in which shoulders are not tied and dowel bars are provided in the transverse joints, results obtained were maximum as follows: - Table 6 Results induced in pavement type (No Tied Concrete Shoulders+ Transverse Joints Have Dowel Bars) S. No. BUC analysis for CBR-9 condition & M50 grade RESULTS Single Axle Load (190KN) Tandem Axle Load (390KN) 1. Maximum Fatigue Stresses 2.777 MPa 2.345 MPa 2. Maximum Cumulative Fatigue Damage 0.598 0.000 2) The rigid pavement having slab thickness of 0.29m in which shoulders are tied and dowel bars are not provided in the transverse joints, results obtained were maximum as follows: - Table 7 Results induced in pavement type (Tied Concrete Shoulders+No Transverse Joints Have Dowel Bars) S. No. TDC analysis for CBR-9 condition & M50 grade RESULTS Single Axle Load (190KN) Tandem Axle Load (390KN) Tridem Axle Load (545KN) 1. Maximum Fatigue Stresses 2.686 MPa 2.720 MPa 2.626 MPa 2. Maximum Cumulative Fatigue Damage 0.210 0.400 0.030 3) The rigid pavement having slab thickness of 0.305m in which shoulders are not tied and dowel bars are provided in the transverse joints, results obtained were maximum as follows: - Table 8 Results induced in pavement type (No Tied Concrete Shoulders+ Transverse Joints Have Dowel Bars) S. No. BUC analysis for CBR-10 condition & M50 grade RESULTS Single Axle Load (190KN) Tandem Axle Load (390KN) 1. Maximum Fatigue Stresses 2.776 MPa 2.343 MPa 2. Maximum Cumulative Fatigue Damage 0.591 0.000 4) The rigid pavement having slab thickness of 0.29m in which shoulders are tied and dowel bars are not provided in the transverse joints, results obtained were maximum as follows: - Table 9 Results induced in pavement type (Tied Concrete Shoulders+ No Transverse Joints Have Dowel Bars) S. No. TDC analysis for CBR-9 condition & M50 grade RESULTS Single Axle Load (190KN) Tandem Axle Load (390KN) Tridem Axle Load (545KN) 1. Maximum Fatigue Stresses 2.684 MPa 2.719 MPa 2.625 MPa 2. Maximum Cumulative Fatigue Damage 0.207 0.395 0.030 5) If we provide only dowel bars in the slab, fatigue damage determined approximately 0.000 in the TDC analysis in most cases vice a versa if we provide only the tied concrete shoulders in case of BUC analysis i.e. this concludes that if we either provide only one of them, the safe design thickness requirements of the slab starts rising. 6) It can also be concluded that the safe design thickness requirements are less in the rigid pavement having shoulders tied and dowel bars are provided in the transverse joints and fatigue damage is very less in the BUC analysis and approximately 0.000 in the TDC analysis. 7) This can be concluded by the following table that as we increase the grade of the concrete mix, the safe design thickness requirements of the slab decreases. Table 10 Comparison of grade with slab thickness for CBR-9 S.No. Type of pavement considered M40 M45 M50 1. No Tied Concrete Shoulders + Transverse Joints Have Dowel Bars 0.33m 0.32m 0.305m 2. No Tied Concrete Shoulders + No Transverse Joints Have Dowel Bars 0.335m 0.322m 0.306m 3. Tied Concrete Shoulders + No Transverse Joints Have Dowel Bars 0.325m 0.31m 0.29m 4. Tied Concrete Shoulders + Transverse Joints Have Dowel Bars 0.285m 0.275m 0.26m

References

[1] Liu, Chiu; McCullough, B. Frank; Oey, Hong S. (2000). Response of Rigid Pavements due to Vehicle-Road Interaction. Journal of Transportation Engineering, 126(3), 237–242. [2] Taghavi Ghalesari, Abbasali; Aguirre, Nancy; Carrasco, Cesar J.; Vrtis, Michael; Garg, Navneet (2020). Evaluation of the response from the rigid pavement analysis system (RPAS) program for the characterisation of jointed concrete pavements. Road Materials and Pavement Design. [3] Hiller, Jacob; Roesler, Jeffery (2002). Transverse Joint Analysis for Mechanistic-Empirical Design of Rigid Pavements. Transportation Research Record: Journal of the Transportation Research Board, 1809. [4] V.A. Sawant et al, “Dynamic analysis of rigid pavement with vehicle –pavement interaction”, Journal of Pavement Engineering, Vol. 10, No. 1, February 2009, 63–72. [5] Yu, Xinhua; Wu, Xiaochun (2010). [IEEE 2010 2nd International Conference on Information Engineering and Computer Science (ICIECS) - Wuhan, China (2010.12.25-2010.12.26)] 2010 2nd International Conference on Information Engineering and Computer Science - Joint Load Transfer Efficiency of Rigid Pavement Considering Dynamic Effects under a Single Moving Load. [6] Jeng-Hsiang Lin et al, “ANALYTICAL STUDY OF PROBABLE PEAK VEHICLE LOAD ON RIGID PAVEMENT”, journal of transportation engineering, volume 126 issue May 2000. [7] Agnihotri, Arvind Kumar; Reddy, Krishna; Bansal, Ajay (2019). [Lecture Notes in Civil Engineering] Sustainable Engineering Volume 30 (Proceedings of EGRWSE 2018) || Economy of Design of Rigid Pavement with Tied Concrete Shoulders. [8] Vishal B Shinde ,Rakesh Kumar To Analyze Bond Strength Between Dowel Bar And Blended Pavement Quality Concrete --Palarch’s Journal Of Archaeology Of Egypt/Egyptology 17(9). ISSN 156-214x. [9] Ioannides, Anastasios M.; Korovesis, George T. (1992). Analysis and Design of Doweled Slab?on?Grade Pavement Systems. Journal of Transportation Engineering, 118(6), 745–768. Hu, Chichun; Ma, Jiexian; Yu, Yuan; Luo, Yi (2016). Optimal design on dowel length for cement concrete pavement. International Journal of Pavement Research and Technology, 9(6), 414–423. [10] Mahboub, Kamyar C.; Liu, Yinhui; Allen, David L. (2004). Evaluation of Temperature Responses in Concrete Pavement. Journal of Transportation Engineering, 130(3), 395–401. [11] Masad, Eyad; Taha, Ramzi; Muhunthan, Balasingam (1996). Finite-Element Analysis of Temperature Effects on Plain-Jointed Concrete Pavements. Journal of Transportation Engineering, 122(5), 388–398. [12] Faraggi, V., Jofre?, C. and Kraemer, C., 1987. Combined effect of traffic loads and thermal gradients on concrete pavement design. Transportation Research Record, 1136, pp.108-118. [13] Belekar Yuvaraj, “Effect of Dynamic Load on Rigid Pavement”, International Journal of Engineering Research & Technology (IJERT), Vol. 4 Issue 03, March-2015. Lee, Ying-Haur; Lee, Ying-Ming (1996). Corner Stress Analysis of Jointed Concrete Pavements. Transportation Research Record: Journal of the Transportation Research Board, 1525(1), 44–56. [14] Thompson, W.E., 1963. Analysis of dynamic behaviour of roads subject to longitudinally moving loads. Highway Research Record. [15] Lee, Ying-Haur; Bair, Jean-Hwa; Lee, Chao-Tsung; Yen, Shao-Tang; Lee, Ying-Ming (1997). Modified Portland Cement Association Stress Analysis and Thickness Design Procedures. Transportation Research Record: Journal of the Transportation Research Board, 1568(), 77–88.

Copyright

Copyright © 2022 Abhishek Pandit, Abhishek ., Dr. Hemant Sood, Er. Jyothi P. M.. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41699

Publish Date : 2022-04-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online